Because you need gear storage that works as hard as you do, we engineered a roof box that’s durable, aerodynamic and built with the kind of resilience plastic can’t match.

Isma-eel Ariefdien, engineering technical lead, worked on two previous iterations of a roof box before settling on this new design. After much debate on whether it was time we make our first plastic product, the team realised that although this was the easier route, it contradicted everything that we stand for.

We were reminded of our favourite maxim – when we start to see airplanes made from plastic then we’ll reconsider our preferred material: aluminium. Speaking to Ish, the journey to our new Slimline Roof Box wasn’t an easy one. The first aluminium prototype was too coffin-like. The less said about the second the better. However, when allowed to think outside of the box, design freedom resulted in the product we’ve landed on. Read on to discover the story of our new Slimline Roof Box, as told by Ish.

Product Purpose

Currently in the overlanding market, you either get plastic roof boxes or ugly square metal boxes. We wanted to develop something that was the same high quality as our large roof box, but more aerodynamic and universal. Something that could fit smaller vehicles, midsize SUVs as well as overlanding trucks. The challenge was keeping the benefits of plastic (lightweight, easy to lock and waterproof) while using sheet metal, which has more limitations.

Key Innovations

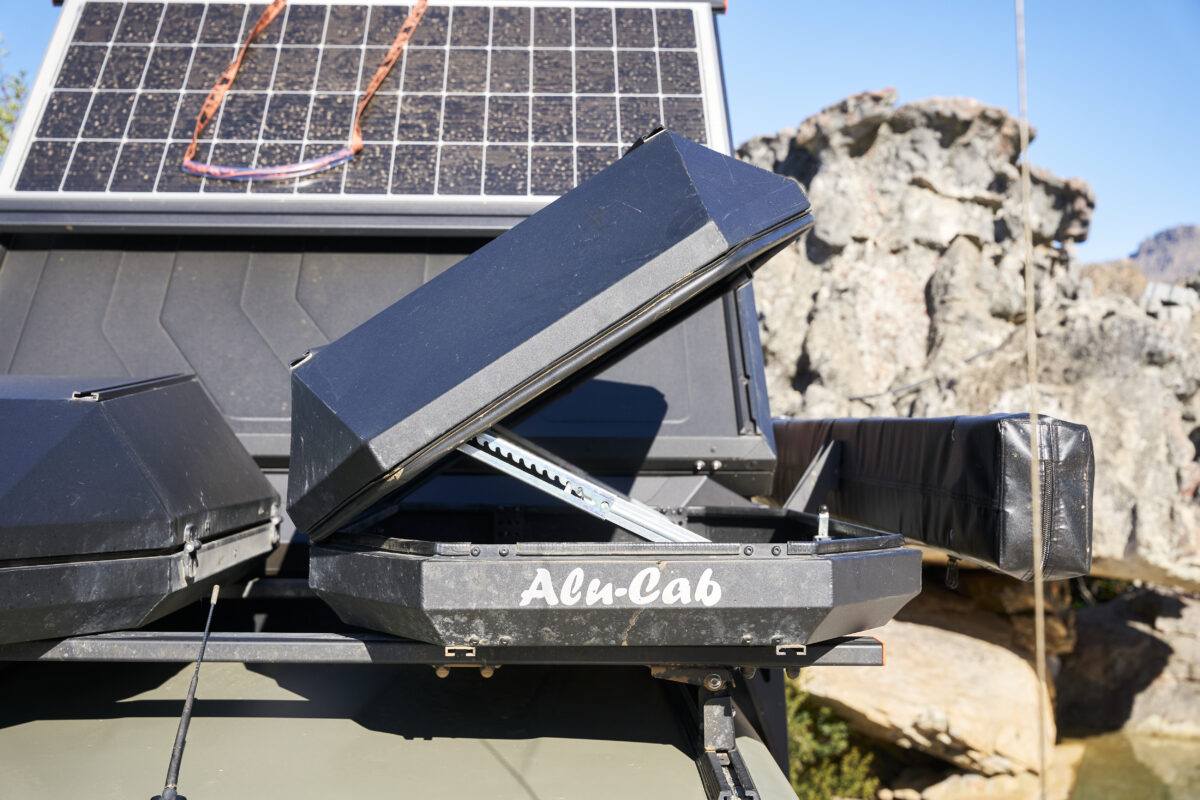

We avoided expensive custom tooling by using existing components for this roof box’s opening mechanism. What makes it unique is the air pressure vent, which prevents condensation inside of the roof box. We also used our proven solar seal from our rooftop tents and a compression push-button lock system where the lid seals downward onto the base, unlike traditional side-latching boxes. It also features mounting rails on top for added modularity, something other roof boxes lack.

Manufacturing Challenges

Sheet metal has inherent constraints, limited by sheet sizes and manual bending processes where even half-degree errors ruin fitment. Every added bend complicates fabrication. We deliberately avoided extruded aluminium to keep it welded and manufacturable. The shape had to balance aesthetics with production feasibility where more complex curves would make it impossible to manufacture or ugly.

Boxing Clever

I think it’s important to emphasise the aluminium construction. Unlike plastic boxes that break on impact, this withstands serious beating. I’d like to highlight the durability, lifespan and those top rails for mounting additional gear. It’s a proper overlanding-grade solution, not just another storage box.

Personal Reflections

This third version was much smoother process than the previous attempts. It was far less frustrating than the first coffin-shaped prototype where we had strict constraints. Being trusted to execute the vision properly made all the difference in reaching this final design.

Key Takeaways

- Aerodynamic aluminium alternative to plastic/steel boxes

- Positive pressure vent system

- Top-mounted rail system for modularity

- Durable overlanding solution